How To Clean A Lever Action Rifle: Part-by-Part Maintenance Guide

Posted by Ranger Point Team on Dec 19th 2025

Lever action rifle cleaning involves these key steps: gather the right tools and supplies, safely field-strip the rifle, clean each component (barrel, action, stock, lever), reassemble, and perform function checks.

How often should you clean a lever action rifle? Short answer: after every use for wet or dirty conditions or defensive use, monthly for regular range use, and a deep annual service for storage or high-mileage rifles. Done right, maintenance keeps your lever running smooth, accurate, and trouble-free, and saves you from expensive gunsmith bills later.

Tools & Supplies You Should Have on the Bench

- Bore brush and cleaning rod (correct caliber)

- Solvent and quality bore cleaner (non-corrosive)

- Patches and a patch jag or loop

- Nylon brushes and toothpicks or pipe cleaners for tight crevices

- Q-tips or microfiber swabs

- Thin film gun oil and a light grease for action rails

- Soft cloths and a toothbrush or brass brush for stubborn fouling

- Soft-jawed vise or gun cradle, and safety gear (gloves, eye protection)

Pro tip: avoid household oils. Use products designed for firearms; they’re engineered to stop rust and not gum up the action.

Rifle Installation Guides - https://rangerpointstore.com/installation/

1. Prep & Safe Disassembly (Model Notes Included)

- Unload and double-check: Remove all ammunition, open the action, and both visually and physically (feel, and use a light) inspect the magazine and chamber. Safety first, always.

- Work on a clean, well-lit bench: Lay a towel to catch small parts.

- Refer to model-specific guides: Henry and Marlin designs are straightforward, but they differ. Henry often has easy receiver top rails and simple takedown pins. Marlin 336 or 1895 may need magazine tube checks or forend removal. When in doubt, follow the manufacturer’s disassembly steps.

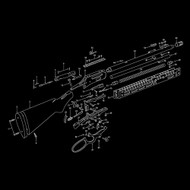

- Basic field-strip sequence (generic): remove forend or handguard, remove lever or trigger group as required, separate barrel from receiver if your model allows, and pull bolt or bolt carrier components where applicable.

If your rifle has a threaded muzzle device or a fitted forend, take note before you remove parts; some kits need special steps.

2. Barrel Cleaning (Step-by-Step)

- Attach the correct bore brush to the rod, apply solvent, and run from chamber to muzzle (never reverse).

- Let solvent sit 5-10 minutes for heavy copper or lead fouling.

- Run brushes until the patches come out clean, then finish with a lightly oiled patch to protect the bore.

- Inspect the crown and muzzle for nicks or damage; a damaged crown kills accuracy.

Frequency: after every use for corrosive or dirty ammo, monthly for routine shooting, and annual deep cleaning for storage.

3. Action & Lever Mechanism Cleaning

- Use nylon brushes and solvent to remove carbon and powder from the bolt, carrier, lever pivot, and rails.

- Use pipe cleaners or Q-tips for the extractor and small cavities.

- Lightly lubricate rails and lever pivot with a thin film of oil; grease high-load surfaces sparingly.

- Reassemble the trigger group and cycle the action by hand; it should be smooth without binding.

Common spots that foul: magazine tube follower area, extractor face, and the inside of the receiver where the bolt rides.

Frequency: oil wipe down after every trip to the range; deeper clean scrubs monthly or after heavy firing.

4. Stock, Forend & External Metal Care

- Wood stocks: wipe with a slightly damp cloth for dirt, then apply a thin coat of stock oil if needed. Avoid saturating the wood.

- Synthetic stocks: clean with mild soap and water; inspect for cracks or loose hardware.

- External metal: wipe down with oil-dampened cloth to stop fingerprints and rust. Pay attention to screws, sling studs, and mag-tube end caps.

Frequency: external wipe after every use; annual check for wear and fit.

5. Reassembly & Function Testing

- Reassemble in reverse order, making sure pins and screws seat properly.

- Cycle the action dry several times to confirm smooth operation and correct timing.

- Function test: with an empty chamber, check trigger reset, lever lockup, and magazine feed (dry load).

- Finally, perform a live-fire confirmation at the range with a 3-round group to verify zero.

If anything feels gritty, stop and re-inspect. Find and fix Don’t “run it in,” ffix theix the root cause.

Rifle Installation Instructions - https://rangerpointstore.com/installation/

Maintenance Schedule (Quick Reference)

- After every use: bore patch, wipe metal, check for visible fouling.

- Monthly: full action wipe, light lubrication, inspect screws and fittings.

- Annually: deep strip, ultrasonic or solvent bath for small parts if needed, inspect crown, and replace worn springs or followers.

- Heavy-use (competition or hunting seasons): deep clean every few hundred rounds or after extended exposure to dirt or salt.

Product Categories - https://rangerpointstore.com/categories/

FAQs

Q1. How often should I clean my lever action rifle?

Clean it after every use when hunting, in dirty conditions, or after using corrosive ammo. For regular range work, a basic bore pass and external wipe after each session plus a monthly action cleaning is a good rule of thumb. An annual deep service (strip, deep solvent, inspect wear parts) keeps older rifles healthy. Think of it this way: a well-maintained lever is a reliable lever, neglect it and you’ll be buying parts (and excuses).

Q2. What tools do I need to clean a lever action rifle?

At minimum: the correct bore rod and brush, solvent, patches, nylon brushes, and quality gun oil. Add a torque-capable driver, calipers, and a bore laser if you want pro-level repeatability. Cheap improvisation costs time and parts; spend on the right tools and your rifle will thank you.

Installation Guides - https://rangerpointstore.com/installation/

Q3. How do I disassemble a lever action rifle for cleaning?

Follow the manufacturer’s sequence: unload, remove forend, remove lever or trigger pins as required, and pull the bolt or bolt carrier where the design allows. Henry and Marlin differ in little ways, so refer to RPP installation or model-specific guides if anything looks unfamiliar. Don’t force pins; if it’s tight, consult the manual or a tech.

Q4. What's the best way to clean the lever action mechanism?

Use solvent and nylon brushes to clear carbon in the rails, bolt, and lever pivot. Clean the extractor and magazine follower with pipe cleaners. Lightly lubricate sliding surfaces and use grease on high-wear spots. Reassemble and cycle by hand; smoothness is the goal, and remember a little oil goes a long way! not excess oil.

Q5. How do I know if my rifle needs professional cleaning?

If you find a damaged crown, cracked stocks, broken springs, or persistent feeding failures after cleaning, bore corrosion or if you aren’t comfortable stripping certain parts, it’s time for a gunsmith. Also, if your rifle has corrosion inside the bore or receiver., professional ultrasonic or chemical services can save the metal.